What certifications do you hold for your facility and products?

Amphenol Custom Cable takes pride in having achieved and maintains the following certifications: ISO9001:2015, TL-9000:2016-H R/6.3/5.7 certified Quality Management System conducted in our site facility at 3221 Cherry Palm Drive. Tampa FL 33619 United States of America. Manufacturing Fiber Optic cables IAW Telcordia GR-326 CORE Issue 4 Fiber, industry recognized Antritsu PIM/Sweep testing, Training in IPC/WHMA-A620 by certified IPC/WHMA-A620 on-site CIT.

What does TL-9000 mean to me and the products you manufacture?

TL-9000 is a very stringent standard to which our quality management system (QMS) is audited annually and certified. An organization's QMS is its life blood and directly translates to how well products are manufactured and how efficiently all other departments deliver on customer requirements and expectations. Amphenol Custom Cable continues to perform at best-in-class levels and is one of fewer than 10 US-based organizations that hold this certification for cable assemblies.

What is GR 326 Issue 4 and what do your certifications represent?

Telcordia GR-326 is a set of standardized quality requirements for the production of fiber optic connectorized assemblies. Amphenol Custom Cable fiber products have been independently certified to these requirements. This ensures our fiber products will perform as well in 20 years as they do the day you receive them, guaranteed.

Some organizations claim their fiber products are GR-326 compliant. What is the difference between compliant and certified?

We are glad you asked. Compliance means the fiber product meets a specific physical specification the day it is manufactured, which does not assure extended life or network performance and reliability at higher speeds. Certification requires compliance to all optical loss performance and endface geometry requirements AFTER completion of ALL of the testing, which is rigorous and extensive. Amphenol Custom Cable is on a short list of manufacturers whose products are approved for use in some of the most stringent telecommunications networks in the world. Custom Cable has been certified by an independent third party testing laboratory to 100% of ALL mechanical, environmental and long term reliability requirements (above) in the latest GR-326 Issue 4 standard.

Networks are deployed for years and the capacity demands are constantly increasing. GR 326 certified products are deployed by the most demanding customers to ensure an extended life, network optimization and a lower cost of ownership.

Do you hold any quality certifications specific to the copper assemblies you build?

Absolutely! We are a global company and our products are manufactured to international standards, per IPC/WHMA-A-620 workmanship standards. This standard is recognized by all major OEMs and defense organizations ensuring consistent quality of skilled workmanship. The standard covers all aspects of wire harness and assembly manufacturing including wire/cable stripping, soldering, and crimping/inserting of connector contacts. Certified trainers are on staff and 100% of our assemblers are trained to these standards.

Can Amphenol Custom Cable PIM and Sweep Certify its RF products?

We sure can. Amphenol Custom Cable has extensive testing capabilities and tests its cables according to industry and customer specifications as required. Our engineers are Anritsu certified to assure our products are tested to the highest standards in the industry.

Does Amphenol Custom Cable test every cable it makes?

We inspect, test and qualify every assembly we manufacture, from basic patch cords to complex wire harnesses, to ensure our clients receive the highest quality possible. All products are tested prior to shipping and are labeled with a unique JOB number for field traceability. Assemblies are serialized and the individual test data is archived and/or shipped with the product.

Can Amphenol Custom Cable provide samples or "first piece" articles for testing?

We can and we do! One way to get the right cable is to detail the requirements up-front and sometimes a first article is required to be sure.

How do you ensure the long term reliability of your products?

By starting with the end in mind, Amphenol Custom Cable designs long term reliability into its products. This commitment is evident in the depth of our QA and Engineering department, which is continually researching the latest manufacturing technology and developing new processes to ensure our products not only work, but are best-in-class. Period. Whether it is via our in house temperature & humidity environmental chamber, custom engineered production tooling, or the latest automation equipment, we are committed to producing products that outlast their application.

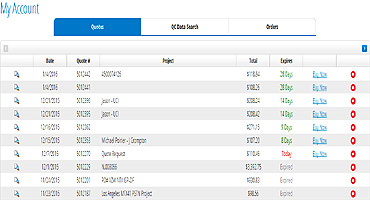

Can I get test data for a cable after it has shipped?

No worries, we have you covered. All assemblies we ship are uniquely serialized and this serial number is located on the cable assembly label. It is a number string beginning with the letter "J". Simply click on the "QA Search" link at the bottom of this page and enter this number.

Fiber Jumpers

Fiber Jumpers

Multi-Fiber Cables

Multi-Fiber Cables

MTP® / MPO Cables

MTP® / MPO Cables

MTP® / MPO Cassettes

MTP® / MPO Cassettes

QSFP

QSFP

MDU & Flat Drop Cables

MDU & Flat Drop Cables

Multi-Fiber Cables

Multi-Fiber Cables

MTP® / MPO Cables

MTP® / MPO Cables

CATV Node Cables

CATV Node Cables

OptiTip™ Cables

OptiTip™ Cables

AARC® FTTAntenna

AARC® FTTAntenna

FullAXS®

FullAXS®

Fiber Optic Cleaners

Fiber Optic Cleaners

Cable Ties & Labels

Cable Ties & Labels

Launch Reels

Launch Reels

Outside Wall Mount Enclosures

Outside Wall Mount Enclosures

Inside Wall Mount Enclosures

Inside Wall Mount Enclosures

Rack Mount Enclosures

Rack Mount Enclosures

Adapter Plates

Adapter Plates

Panels

Panels

Attenuators

Attenuators

Fiber Optic Loopbacks

Fiber Optic Loopbacks

SFPs

SFPs

Splitters

Splitters

Cat 5E

Cat 5E

Cat 6

Cat 6

10G & 40G SFP Assemblies

10G & 40G SFP Assemblies

DS 1 – Champ

DS 1 – Champ

DS 3 - Coaxial

DS 3 - Coaxial

ASYNC

ASYNC

RET Cables

RET Cables

HDPP Panels

HDPP Panels

Copper Adapters

Copper Adapters

Outside Wall Mount Enclosures

Outside Wall Mount Enclosures

Inside Wall Mount Enclosures

Inside Wall Mount Enclosures

Rack Mount Enclosures

Rack Mount Enclosures

Racks

Racks

Cabinets

Cabinets

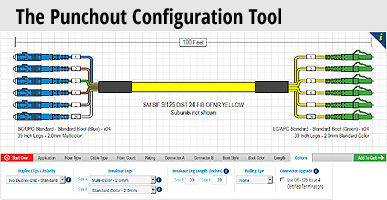

designator for the Product Category Configurator

designator for the Product Category Configurator

What does Amphenol Custom Cable do?

What does Amphenol Custom Cable do?

- Follow Us

- Follow Us